Ship a Pallet in 15 Easy Steps: A Beginners’ Guide

How to Ship a Pallet Step-by-Step: Choose the Pallet Type & Size, Package & Prepare Your Pallet for Shipping

[Updated June 2023]

You’re new to pallet shipping, and want to save time and money by doing things yourself.

So, where do you start?

There’s a ton of information on the Internet, but it’s all over the place, with a ton of complicated freight jargon you’re not familiar with. You’ve also heard horror stories from colleagues about their pallets breaking down, shipments getting damaged, and carriers refusing their improperly packaged freight.

You want to do it, do it right, and do it right the first time. We get that.

And we’ve got your back. This guide for pallet shipping is designed for beginners but still sharp enough to be useful to veterans. Everything you need to know is here, along with useful visuals.

Our contact info is at the bottom of the post, in case you have any questions after reading.

Let’s begin!

1. What is a pallet?

A pallet is a flat structure made of wood, plastic, composite, or metal, on which freight is secured for shipping. It has both a top and a bottom deck, and its raised construction allows the forks of a pallet jack or forklift to slide under the pallet in order to move it.

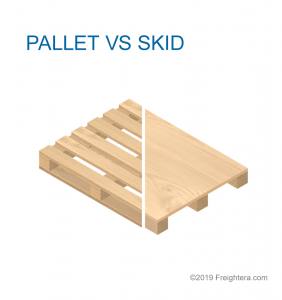

2. What is the difference between a pallet and a skid?

The main difference between a pallet vs. a skid is that a pallet has both a top and a bottom deck, while a skid only has a top deck. Pallets are usually used for transportation of freight, while skids are mainly used for storage.

3. How many types of pallets are there?

Based on the pallet style, we can differentiate between these two main pallet types:

-

Stringer pallets

-

Block (or deck board) pallets

Stringer pallets have three parallel pieces of wood which support the boards of wood. They’re also called 2-way pallets because the forks of a forklift or a pallet jack can only pick them up from two different sides:

Block (deck board) pallets are 4-way pallets: they can be picked up from all sides. Blocks of wood on the middle of each edge and on the sides provide more support from the platform, which makes this type suitable for heavier shipments:

There are many subcategories within these two categories. We can differentiate between these pallet types:

-

Double Face Pallets

-

Single-Wing Pallet

-

Double Wing Pallets

-

Solid Deck Pallets

-

Flush Pallets

-

Non-Reversible Pallets

-

Reversible Pallets

- Double Face Pallets can be used with any side up. Their two decks increase the pallet strength.

- Single Wing Pallets have either top deck boards or bottom deck boards extending beyond the edges of the stringers. This also increases how much weight the pallet can carry.

- Double Wing Pallets have both top and bottom deck boards extending beyond the edge of the stringers, which offers additional surface area.

- Solid Deck Pallets have no spacing between the deck boards, but a single sheet of material, making them easier to clean than regular pallets.

- Flush Pallets have all edges completely square: deck boards and stringers flush along the sides of the pallet and there is no overhang.

- Non-Reversible Pallets have a bottom part with a different configuration than their top part, which means they cannot be turned upside down.

- Reversible Pallets have identical top and bottom parts and can be turned any side up.

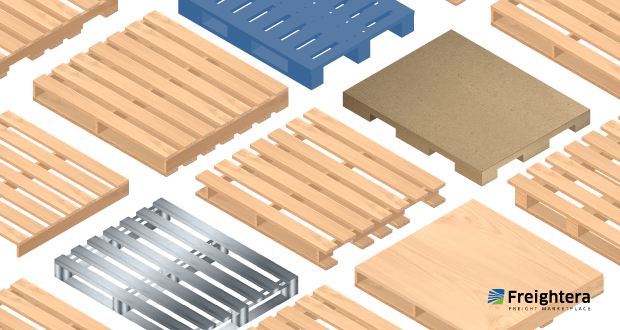

4. What are pallets made of?

There are several types of pallets based on the material they’re made of:

-

Wooden pallets

-

Presswood pallets

-

Plywood pallets

-

Metal pallets

-

Plastic pallets

-

Corrugated board pallets

Pallets that are most commonly used in freight shipping are metal, wood, and plastic pallets.

5. What is the difference between wooden, plastic, and metal pallets?

Wood pallets vs. plastic pallets vs. metal pallets: which ones to choose?

Wooden Pallets

Wooden pallets are durable, they can handle a lot of weight, and they’re easy to repair, recycle and reuse. Their biggest drawback is their weight, which may increase the cost of the shipment. Also, wood is easily damaged by moisture, and splinters and other pallet deformations may cause injuries.

Plastic Pallets

Plastic pallets weigh less than wooden pallets and are strong enough and safe to handle. They’re resistant to humidity and corrosion, which increases their lifespan. However, they’re not as easy to repair as wooden pallets, they’re non-recyclable and more expensive than both their wooden and metal counterparts.

Metal Pallets

Metal pallets can handle more weight than both wooden and plastic pallets. They’re also cheaper, easily sanitized, and do not corrode over time. Their main disadvantage is that they’re hard to repair, and are heavier than plastic pallets, which can increase the shipping cost.

6. How to choose the right pallet type for shipping?

Set your budget

First, set your budget. Some pallets are cheaper than others, some can be used for a longer time, and some can be easily recycled.

Consider the packaging material

Second, determine which material suits your transportation needs best. Is your freight heavy or light?

Choose the right pallet size and type

Third, choose the size and type of pallets based on your transport and storage limitations.

7. What sizes do pallets for shipping come in? What are the standard pallet dimensions?

The plurality of pallets used in North America is determined by the GMA (Grocery Manufacturers Association) pallets, with dimensions of 48″ x 40″. These are considered the standard pallet dimensions.

The next most common pallet sizes are 42” x 42” and 48” x 48”.

Below is the table of all pallet sizes used in North America, with dimensions in inches, millimeters, and industries in which they’re mostly used:

| Dimensions in inches (Length x Width) |

Dimensions in mm (Length x Width) |

Usually used in: |

|---|---|---|

| 48” x 40” | 1219 x 1016 | Most industries, including food |

| 42” x 42” | 1067 x 1067 | Telecommunications |

| 48” x 48” | 1219 x 1219 | Drum shipping |

| 48” x 42” | 1219 x 1067 | Chemicals & Beverage shipping |

| 40” x 40” | 1016 x 1016 | Dairy industry |

| 48” x 45” | 1219 x 1143 | Automotive industry |

| 44” x 44” | 1118 x 1118 | Drums & Chemicals shipping |

| 36” x 36” | 914 x 914 | Beverage shipping |

| 48” x 36” | 1219 x 914 | Lumber & Paper industries |

| 45.5” x 36” | 1156 x 889 | Military 1/2 ISO Container |

| 48” x 20” | 1219 x 508 | Retail |

8. How to choose the right pallet size?

Your choice of pallet size depends on what you’re shipping, where you’re shipping it, and how you plan to load and unload your freight. Start with your industry and product: businesses in one industry tend to use the same pallet size because the size of packages is usually constant (refer to the table above for examples). Next, think of the size of your warehouse, and the size of forklifts used for loading and unloading.

9. What is the weight of an empty pallet?

An average 48” x 40” pallet will weigh between 33 lbs and 48 lbs. Most pallets weigh around 30 lbs, but some pallets can weigh up to 70 lbs depending on the material they’re made of, their load-bearing capacity, and their moisture level.

10. How much can you put on a pallet?

Standard pallets can carry between 3,700 and 4,600 lbs. Pallet capacity depends on the pallet dimensions, type, and material it’s made of.

11. How many cartons fit on a pallet?

The number of boxes that fit on a pallet depends on the pallet dimensions, size of the boxes, how you stack them, and how high you stack them.

Use this pallet loading calculator to help you see how many items of the same size and weight you can put on a single pallet. You can choose the metric or the imperial system. Then enter the dimensions and weight, and you’re good to go! We’ve tested this tool and it looks pretty accurate (it’s only simple math), and the only drawback is that it supports only simple item stacking and cannot take complex box rotations into account, meaning that it can only calculate if it assumes that every item is placed in the same way relative to the base.

12. How high can you stack a pallet?

In general, standard-sized pallets shouldn’t exceed 60” in height. Boxes should be stacked with the heaviest on the bottom, and the lightest on top, and they shouldn’t lean one way or hang over the perimeter of the pallet. This is important for the safety of the people who will load and unload your cargo. All pallets should be safe to move and unpack.

If it’s impossible to keep the height of a pallet, make sure that it’s strapped to the pallet as safely as possible and keep in mind that the standard height of a truck is 96”.

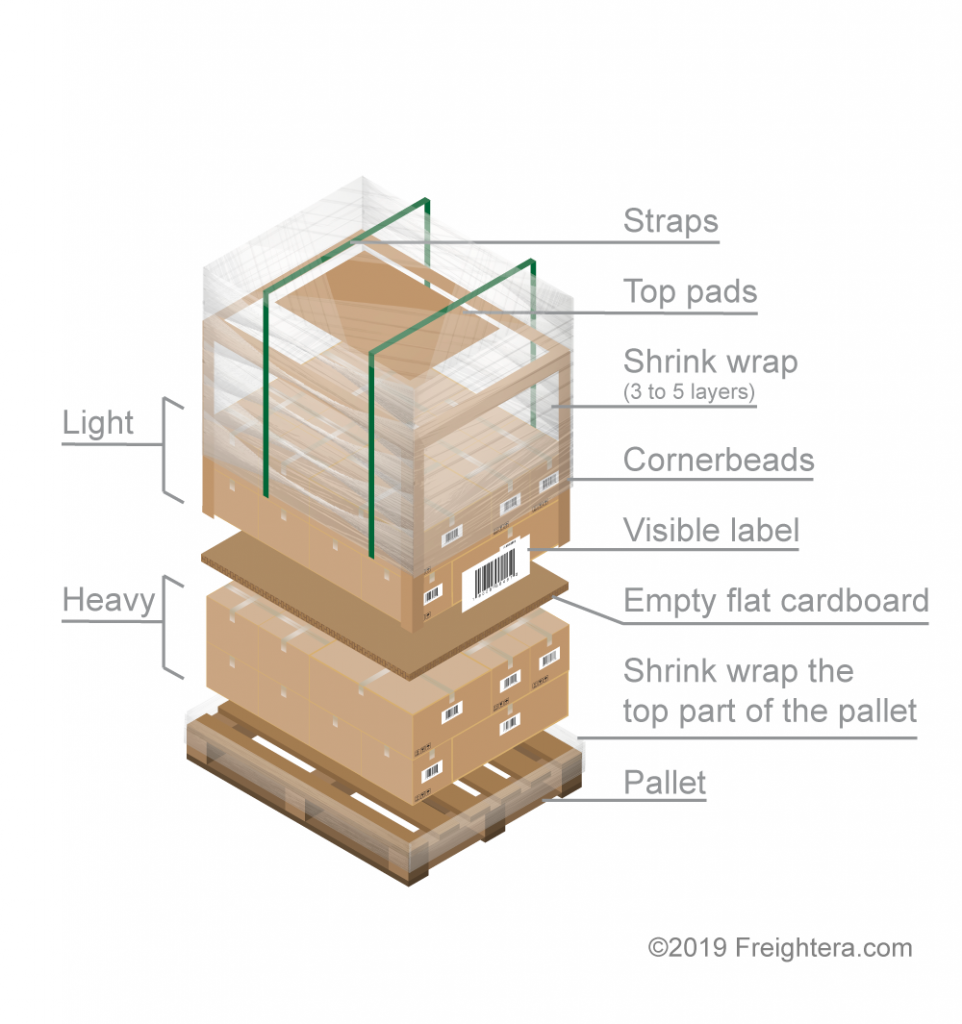

13. How to prepare a pallet for shipping?

-

Pack your products in individual boxes with care: use high-quality cartons;

-

Use bubble wrap and foam peanuts for cushioning. Make sure the boxes are completely filled: any extra air may lead to damages on the inside;

-

Use enough high-quality tape to prevent your boxes from tearing;

-

Stack your boxes so that heavier ones are on the bottom and lighter on top;

-

Distribute the weight evenly;

-

Make sure the pallet is not too high, and that boxes are not leaning one way or hanging over the edge of the pallet;

-

Use flat empty cardboard every couple of rows;

-

Use corner beads around the edges of the pallet;

-

Make sure to use quality shrink wrap;

-

Shrinkwrap the pallet liberally: make sure the shrink wrap adheres to the product, and wrapped around the pallet at least 3 times.

14. How many pallets fit on an LTL truck?

Less-than-truckload (LTL) shipments can typically fit between 1 and 6 pallets.

15. How many pallets fit in a 53-foot truck?

A full truckload (a completely filled 53’ truck) can hold from 24 to 30 pallets.

To sum up:

- A pallet is a flat structure used for shipping freight.

- Most often, pallets are made of wood, plastic, or metal.

- Usually, they’re 48″ x 40″ in size, weigh between 33 lbs and 48 lbs, and can carry between 3,700 and 4,600 lbs.

- There are several different types and sizes of pallets, and you need to consider your budget, transportation needs, and transport and storage limitations in choosing the right one for shipping.

- When it comes to packaging, generally standard-sized pallets shouldn’t exceed 60” in height and should be packaged and prepared for shipping neatly and carefully.

- 1 to 6 pallets fit in an LTL shipment; 24-30 pallets fit in an FTL shipment.

This is it! These are the basics of pallet shipping.

You’re now ready to start shipping your freight! Visit our LTL quoting page now and see how easy it is to get the best available rates and ship pallets online, in seconds, with Freightera. Quotes are instant and all-inclusive.

If you have questions or doubts, don’t hesitate to get in touch! Call our Client Care team to set up a consultation today: (800) 886-4870 Ext. 1, write to us at [email protected], or visit our Help Center!