How to Crate Freight for Shipping

Crating basics for fragile and high-value freight

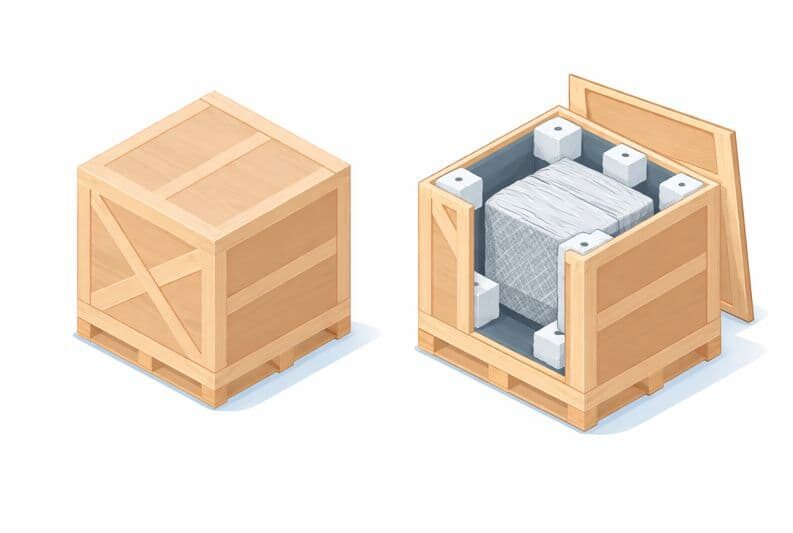

Crating is one of the safest ways to package fragile, high-value, or oddly shaped freight, and it is often required by carriers for certain commodities. A well-built crate turns an exposed, vulnerable item into a rigid, protected unit that can be shipped safely.

This guide explains when crating is worth the added cost, how to design and build a crate that actually protects the load, and what to watch for so your freight shipment moves smoothly.

Why crating matters in freight shipping

Crating changes how your shipment behaves in transit.

- A rigid crate keeps everything together as one unit, even when freight is tipped, bumped, or stacked.

- Fragile or high-value items are often only accepted if they are crated. If packaging is inadequate, carrier liability for damage can be reduced even when the damage clearly occurred in transit.

- A good crate lets you put most of the protection inside (padding around the freight) instead of relying only on the outside wrap.

- Carriers and NMFTA/NMFC standards expect packaging that can withstand normal LTL handling, stacking, and vibration. A properly designed crate helps you meet those expectations and strengthens your position if you ever need to file a claim.

When is crating a better choice than palletizing?

Crating usually makes more sense than palletizing when one or more of the following is true:

- The item is fragile, for example: glass, stone countertops, ceramics, artwork, instruments, or precision equipment.

- The value is high enough that damage would be a major loss, even if you recovered something through a claim.

- The shape is irregular and cannot be stabilized safely on a pallet.

- There are protruding or delicate parts (arms, legs, knobs, sensors, fittings) that could easily snap or bend if exposed.

- The carrier explicitly requires a crate for that commodity in its rules or in your quote notes.

- You are shipping long distances or cross-border LTL, and the freight will be handled many times in terminals and on different trailers.

If you are hesitating between “more wrap on a pallet” and a proper crate — choose the crate for anything fragile, expensive, or hard to replace.

How to properly crate your freight shipment

1) Choose the right crate type

You do not always need the heaviest possible crate, but you do need one that is rigid, intact, and forklift-safe.

Common options include:

- Plywood-sheathed crate: Uses framing (such as 2x4s) with plywood walls. This is a good all-round choice for many industrial and commercial items.

- Solid-wood crate: Built with thicker, solid boards for the walls and base. It is heavier and more impact-resistant, and is often used for very heavy or high-value freight.

- Reinforced crate: A solid or plywood crate with extra framing or steel reinforcement, used when items are extremely heavy, sensitive, or valuable.

Some of the basics to get right:

- The base must allow for forklift or pallet-jack entry on at least two sides.

- Boards and fasteners must be strong enough that the crate will not rack, twist, or break when lifted.

- There should be no broken slats, rotten wood, or large gaps that could let parts of the freight protrude.

If a crate looks weak or “patched together,” carriers are more likely to refuse it or limit their liability for damage.

2) Measure and design for padding

A crate protects best when the freight is surrounded by padding, not pressed tight against the walls.

- Measure the item, including any protrusions, and then add space on all sides for cushioning: usually several centimeters (a couple of inches) around and underneath.

- Leave enough room for foam, honeycomb board, air-cell padding, or layered cardboard so the item is “suspended” inside the crate.

- Avoid designing a crate that is so tight you cannot add protective material, or so loose that you need excessive filler just to stop the freight moving.

Ask yourself, “If the crate tips slightly or the truck hits a pothole, does anything inside have room to swing, fall, or slam into a wall?” If the answer is yes, you need more blocking and padding.

3) Block, brace, and pad the contents

Inside the crate, the goal is zero meaningful movement.

- Block and brace: Use wood blocking, foam blocks, or custom supports to keep the item from shifting forward, backward, or sideways.

- Protect contact points: Wherever the freight touches wood, add padding (foam, corrugated, edge protectors) so vibration does not grind or dent surfaces.

- Fill voids: Do not leave large empty spaces that allow momentum to build; use foam, dunnage, or layered cardboard to fill them.

- Isolate multiple items: If you pack several pieces in one crate, separate them with rigid dividers and cushioning so they cannot collide.

Once packed, gently rock or push the item inside the open crate. If you can feel it moving, add more bracing and padding before you close the crate.

4) Build for handling and stacking

Crates move through the same network as pallets, so design as if they will be:

- Lifted repeatedly by forklifts and pallet jacks

- Stacked or at least top-loaded with dunnage or other freight

- Subject to normal trailer forces: braking, turning, bumps, and dock impacts

Make sure to:

- Provide solid runners or skids under the crate so forks can enter cleanly without breaking boards.

- Keep the center of gravity as low and centered as possible; heavy items should be secured near the base.

- Use diagonal or cross-bracing in the frame if needed to prevent racking.

- Build a top strong enough to support reasonable top-loading or at least to hold dunnage and light freight without collapsing.

A crate that collapses, twists, or sheds pieces is a red flag in terminals and can increase the risk of damage.

5) Close, seal, and label the crate

Once everything inside is blocked and padded, close the crate so it stays secure but can be opened for inspection if needed.

- Use screws, not nails, for the main panels. Screws hold better under vibration and make it easier to remove a panel without destroying the crate.

- Consider designating one side or the top as a “service panel,” so inspectors or receivers can open and re-close the crate cleanly.

- Before closing, photograph the packed interior from several angles; those photos can support a claim if something does go wrong.

After closing, label at least two sides (ideally on all four, including the top) with:

- Shipper and consignee

- Piece count (for example, “Crate 1 of 1”)

- Any accurate handling marks (such as “Fragile”, “This Side Up”, etc.)

Freightera automatically generates the shipping labels with all of the relevant information as soon as you book your shipment.

Important note: Use handling labels only when they are true. “Fragile” and “This Side Up” are helpful when accurate, but they are not a substitute for sound construction and packing. They also may result in your shipment being treated as non-stackable, which is likely to increase the price.

Crating your freight FAQ

Do I always need a crate for fragile items?

Not always, but often. Some lighter, less expensive fragile items can travel in strong cartons on a pallet if they meet carrier packaging standards. For heavy, high-value, or very fragile pieces (such as stone tops, glass, original art, precision machinery), a crate is usually required or strongly recommended.

Can I reuse a wooden crate?

Yes, as long as the structure is still solid: no broken boards, loose fasteners, or soft/rotting wood. You should always refresh the internal padding and blocking to match the new item. If the crate looks tired or banged up, replacing or rebuilding it is safer.

If the carrier says that the freight “must be palletized or crated,” when should I pick crating over a pallet?

Choose a crate when the shipment is fragile, high-value, has delicate protrusions, or could not survive normal bumps and stacking even in heavy cartons on a pallet. A pallet with stretch-wrap is fine for sturdy boxed goods; a crate is better for anything that would be difficult or expensive to replace if damaged.

Can I put more than one item in the same crate?

Yes, but only if you block and pad each item so they cannot hit each other or the walls. Use dividers, foam, and bracing to isolate pieces, and clearly mark the packing list so receivers know what is inside.

How much extra does crating add to my overall shipping cost?

Crating adds packaging material and labor cost up front, and sometimes a bit of weight. However, it can reduce the risk of damage, rework, and claims, especially on long-haul or cross-border LTL shipments. For fragile or high-value freight, crating often lowers your true total cost by preventing loss and delays.

Can I build my own crate, or do I need a professional?

You can build your own crate if you are comfortable working with lumber and follow the basic principles above: rigid frame, forklift-safe base, room for proper padding, and solid closure. For very high-value, heavy, or complex items, many shippers choose professional crating services, especially for repeat lanes.

Should I use a wooden or a metal crate?

A well-built wooden crate offers enough protection for most shipments. A metal crate is recommended for additional protection for particularly fragile, heavy, or cumbersome cargo.