Palletizing Freight: Best Practices

A step-by-step guide to palletizing freight

For most LTL shipments, palletizing is the default. A well-built pallet turns a group of boxes into one stable handling unit that is easier to move, less likely to be damaged, and less likely to trigger surprise fees.

When in doubt, you should palletize your shipment, because shipping loose pieces is riskier, harder to handle, and often not accepted by freight carriers.

Why palletizing matters

Good palletizing does several important things at once:

- Protects your freight from shocks, pressure, and tip-overs by keeping everything tightly unitized on a solid base. The in-transit shock is the #1 cause of cargo damage.

- Makes loading and unloading faster for drivers and terminals, because forklifts and pallet jacks can handle complete units instead of loose items.

- Keeps shipments within carrier packaging standards so they can be stacked, staged, and handled normally in LTL terminals.

- Reduces the odds of reweigh/reclassification, damage claims, and extra charges by presenting freight in a way carriers expect and can easily manage.

Most LTL carriers expect freight to be on a solid pallet that is wrapped, strapped, and labeled. The closer you are to that picture, the smoother your shipment will go.

How to palletize your freight, step by step

1. Choose the right pallet

Start with a sound pallet as your base. For most LTL shipments:

- Use a standard 48×48 inch pallet (or a size that fits your freight without overhang).

- Make sure deck boards are intact, stringers are not cracked, and there is 4-way forklift entry so it can be picked up from any side.

- Avoid broken, missing, or soft boards, as they can fail under load and cause damage.

A strong, undamaged pallet plus proper securement is your first layer of insurance.

2. Box and pad individual items

Before you put your freight on the pallet, package items in individual boxes where possible:

- Use sturdy cartons appropriate for the weight of the contents.

- Fill voids with padding (paper, cardboard cutouts, foam, etc.) so items do not rattle or collapse inside the box.

- Aim for enough cushioning to handle bumps and vibration, but not so much that boxes bulge or lose their shape.

Well-packed boxes give you a solid “building block” to work with when you stack.

3. Build a stable stack

Stack boxes on the pallet with stability and weight distribution in mind:

- Place the heaviest boxes on the bottom and lighter ones on top so your center of gravity stays low.

- Align boxes in straight columns when you can; this is typically the strongest pattern for supporting weight from above.

- Fill gaps between boxes so nothing can shift easily.

It’s better to build one solid, even block of freight rather than a loose “pyramid.”

4. Use layer sheets between rows

Between each layer of boxes, add a flat sheet of cardboard or similar material:

- This spreads weight more evenly and improves shock absorption.

- It prevents corners of upper boxes from pressing directly into the boxes below.

- It keeps the stack more rigid, which helps the wrap and straps do their job.

Layer sheets are a small cost that can prevent crushed cartons and internal damage.

5. Avoid overhang

Your freight should not extend beyond the pallet footprint:

- Keep all boxes and items fully within the edges of the deck boards.

- Overhanging cartons are more likely to be crushed or damaged when pallets are moved close together. They also pose a higher risk to other cargo onboard.

- Overhang can lead to inspections or adjustments if the shipment is harder to handle or protect.

If your load is wider than a standard pallet, use a larger pallet or re-pack so everything stays inside the base.

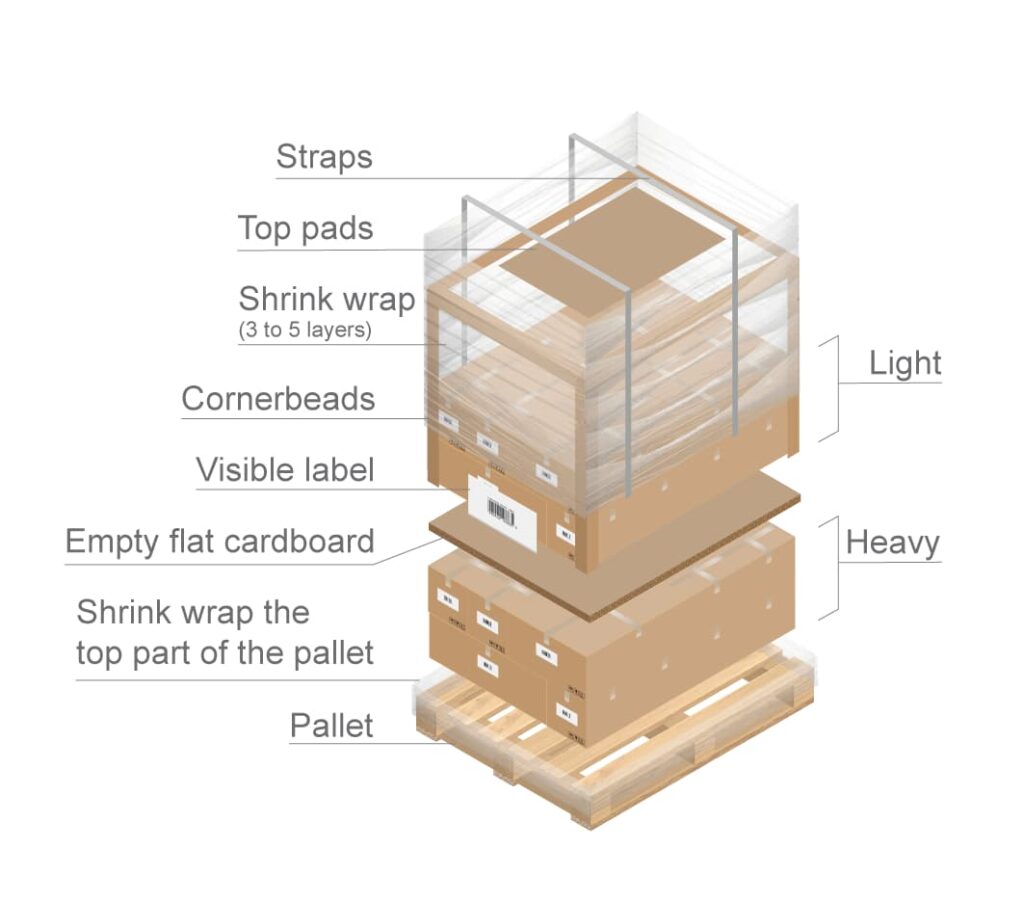

6. Add corner protection

Corner protection is a simple way to strengthen the entire unit:

- Place cardboard corner guards (corner boards) on all four vertical edges.

- This protects vulnerable box corners from impact and wrap tension.

- It adds “column strength” so the stack can better support top load if another pallet is placed on top.

7. Strap the load to the pallet

Wrapping alone is often not enough. Strap the freight to the pallet so it behaves as one unit:

- Use plastic or steel banding.

- Run at least two perpendicular straps through the pallet openings and over the load.

- Tighten enough that the freight cannot slide on the deck but not so tight that boxes are crushed.

Strapping ties the load to the pallet so a sudden brake or turn in transit does not shear the freight off the base.

8. Wrap from the base up

Once strapped, use stretch wrap to contain and unitize the load:

- Anchor the wrap by threading it through the pallet openings or catching it under the bottom deck, then pull tight.

- Make 3–5 full passes around the pallet and load, spiraling from the bottom to the top and back down to the base.

- Keep consistent tension so the wrap pulls boxes tightly together without crushing them.

- For heavier loads or long-haul shipments, additional layers are fine as long as they do not distort the freight.

- The wrap should capture both the cargo and the pallet so everything moves as a single, solid unit.

Making freight safely stackable

Carriers and terminals often stack pallets to use trailer space efficiently. To benefit from stackable handling (and avoid unnecessary non-stackable charges), design your pallet with stacking in mind:

- Finish with a flat, level top surface, without tall single boxes or uneven peaks.

- Use layer sheets and corner boards to spread weight and protect edges.

- Keep the center of gravity low with heavy items at the bottom.

- Only mark “Do Not Stack” when stacking would genuinely risk damage (for example, fragile top items, irregular shape, or insufficient support).

Safely stackable freight is easier for carriers to work with and often cheaper to move.

Labeling and documentation on palletized freight

Clear labeling helps prevent loss, misroutes, and disputes:

- Place shipping labels on at least two adjacent sides, ideally near the top-right corners, on all four sides, and on the top if possible.

- Make sure labels are flat and readable. They should not be wrinkled, folded, or wrapped over edges or straps.

- Avoid covering barcodes with wrap, straps, or additional labels.

- Ensure label details (shipper, consignee, reference numbers, piece count) match your bill of lading (BOL).

More visible, accurate labels mean fewer chances for your freight to disappear on a busy dock.

When palletizing is not enough: consider crating or different methods

Even with good palletizing, some freight needs more protection:

- Crate fragile, high-value, or irregular items that cannot be stabilized on a pallet alone.

- Only ship as a single loose piece if the item is light, low-value, and the carrier has confirmed they will accept it as-is.

If you would be very upset to see the item scuffed, dented, or worse, palletizing or crating properly is almost always worth the cost and the effort.

Common palletizing mistakes to avoid

You’ll be ahead of most first-time shippers, if you avoid:

- Using broken or weak pallets “just this once.”

- Letting boxes overhang the edges.

- Skipping padding inside boxes because “it will be fine.”

- Using only one light layer of wrap around the middle of the load.

- Forgetting to strap the freight to the pallet.

- Placing labels on only one face or where they are hard to see.

Palletizing LTL Freight FAQ

Do I really need to palletize my shipment?

For LTL, yes – almost always. Palletized freight is safer, easier to handle with forklifts, and more widely accepted by the carriers.

When is it better to crate instead of just palletizing?

If the item is fragile, high-value, oddly shaped, or cannot be stabilized as one solid unit on a pallet, crating with proper internal padding is the safer option.

What size pallet should I use for LTL?

For most LTL shipments, a standard 48″ × 40″ pallet works best, because it fits carrier equipment and makes loading easier. If your freight is longer or wider, use a larger pallet instead of letting boxes hang over the edge.he edge.

Can I reuse old pallets or do they have to be new?

You can reuse pallets as long as they are solid and undamaged: no cracked boards, missing stringers, exposed nails, or soft/rotting wood. If a forklift could break it or your freight could fall through, carriers may refuse it or treat it as improperly packaged. Generally speaking, reusing safe and stable pallets is the eco-friendly option.

How much stretch wrap is enough?

A good baseline is 3–5 tight passes around the load and pallet base, from bottom to top and back down. Heavier or higher-value freight may benefit from additional layers plus corner boards and strong banding.

Do I really need both stretch wrap and straps?

For most LTL loads, yes. Straps keep the freight attached to the pallet, and stretch wrap keeps the boxes together as one unit. Using both greatly reduces shifting, leaning, and box damage during normal handling.

How tight should I wrap the pallet?

Tight enough that you cannot easily pull boxes away from the stack by hand. Start at the pallet base, capture the pallet deck with the wrap, then spiral up and back down with 3–5 full passes. If the wrap is loose or “baggy,” it will not hold the load together.

Is it okay if my pallet is a bit top-heavy?

Try to avoid this. A top-heavy pallet is easier to tip when a forklift turns or stops. If you cannot avoid it, use extra strapping, corner boards, and very tight wrap, and keep the height as low as reasonably possible.

Can I mix different products on the same pallet?

Yes, as long as you pack and stack them so nothing crushes or pierces anything else. Put heavier, sturdier items on the bottom and lighter, more fragile items on top, with padding or layer sheets between them. If you’re shipping within the USA, make sure to disclose what you’re shipping for classing purposes.

What if I don’t have boxes for everything I’m shipping?

Whenever you can, box loose items first. If something will not fit in a box, make sure it is well-padded and cannot slide around: use foam, cardboard, or other dunnage, and strap it tightly to the pallet. Unboxed freight is more likely to get scuffed or damaged.

How high can I stack a pallet for LTL?

It depends on the carrier and equipment, but many LTL carriers prefer pallets at or below a standard dock height (around 60 inches). Very tall pallets are harder to stabilize and may be more likely to be treated as non-stackable. A good number to stick to is 48” in height, as that way another pallet of the same height can fit on top of or under yours.

Do I have to label every box, or just the pallet?

At minimum, label the pallet clearly on at least two sides and ideally on all four. If you have many mixed items, labeling individual boxes as well helps prevent misroutes and makes it easier to sort and check counts at delivery.