Dock Alternatives for Freight Loading and Unloading

Loading and unloading freight without a dock: portable ramps, cranes, & truck-mounted lifts

Not every freight pickup or delivery happens at a warehouse with a raised dock and a forklift waiting. If you’re shipping from a small shop, a yard, a job site, or any location where the truck deck sits higher than the ground, you still need a safe way to bridge that height gap.

That is where dock alternatives come in: portable loading ramps for forklift-based freight handling, and crane solutions (including truck-mounted loader cranes like Hiab/knuckleboom) for freight that is too heavy, oversized, or too oddly shaped for liftgates and standard equipment.

This guide explains what each option is best for, and how to choose the simplest method that can actually handle your freight safely.

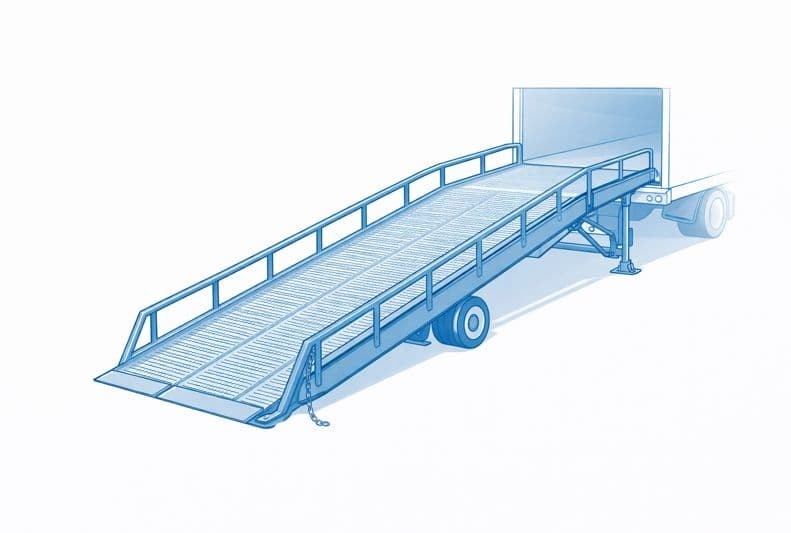

Portable loading ramps: your “plug-in” dock

A portable loading ramp is a mobile, inclined platform that you position at the back or side of a truck, allowing you to move freight with a forklift or pallet jack. In effect, it turns ground level into a temporary dock.

For many small warehouses, yards, and job sites, a ramp is a long-term, flexible alternative to building a dock.

If you ship often enough and you don’t have a dock, consider investing in a portable ramp. Portable ramps are ideal when you need a consistent way to load and unload, rather than relying on liftgates or manual unloading for every shipment.

Portable ramps vs. liftgates

Portable ramps are a strong option when you ship frequently from the same location but don’t have a fixed dock. They give you a repeatable way to load and unload without rebuilding the site around freight.

They also make the most sense when you already have handling equipment access, either on-site or through rentals. If you can use a forklift or pallet jack, a ramp can turn ground-level loading into a smooth, consistent process.

For frequent shippers, ramps can also be a cost-saving strategy: a one-time equipment investment (or a longer-term rental) may be more economical than paying liftgate fees on every shipment.

Where ramps struggle are tight sites. If there isn’t enough room to place the ramp and approach it safely with equipment, it quickly becomes impractical.

They are also less reliable in extreme weather. Ice, heavy rain, mud, or poor traction can turn the slope into a safety hazard.

And finally, a ramp does not solve the human side of the job. If the site does not have trained equipment operators, the labor and safety risks remain, even if you have the right equipment.

If you ship only occasionally and your freight is within typical liftgate limits, it is often simpler (and sometimes cheaper) to add a liftgate to the quote than to rent or buy a ramp and the equipment needed to use it.

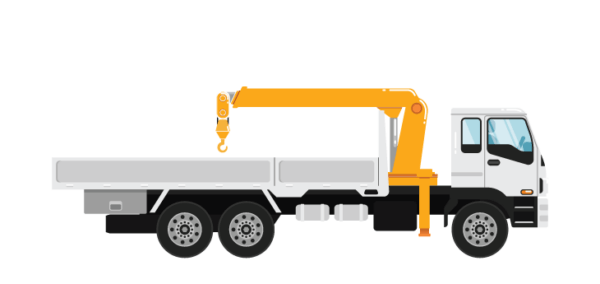

Cranes & truck-mounted lifts (Hiab/knuckleboom)

Sometimes freight is simply too heavy, too long, or too oddly shaped for liftgates, portable ramps, or standard forklifts. That is where cranes and truck-mounted loader cranes come in.

Common use cases for cranes include:

- Very heavy machinery or equipment beyond liftgate or small forklift limits.

- Oversized items that must be lifted off the side or over obstacles (fences, curbs, landscaping).

- Deliveries to construction sites with no dock, ramp, or smooth access.

- Items that need to be placed in a specific elevated position, not just dropped at ground level.

Truck-mounted cranes (often called Hiab or knuckleboom lifts) are particularly useful because they travel with the truck, allowing the driver/operator to both transport and place the freight in one visit.

Permits, lead time, and cost considerations

Cranes and truck-mounted lifts are specialized services. Compared to standard LTL delivery, they usually involve:

- Higher costs: You are paying for special equipment, a trained operator, and extra time on site. Pricing may be hourly with minimums or quoted as a project rate.

- Longer lead times: Equipment and operators need to be scheduled in advance. Last-minute changes can be expensive or impossible to accommodate.

- Permits and local rules (for larger cranes or street work): In some areas, setting up a larger crane or blocking a lane/sidewalk requires permits or traffic control. Carriers or crane companies often handle permitting, but they need time and accurate site details.

The key is to treat crane/Hiab service as a planned project, not a same-day fix for freight that turns out to be too heavy for a liftgate.

How to choose the best dock alternative: a quick way to think about it

If you are not sure, start from the freight itself: weight, size, packaging, and where exactly it needs to end up. Then choose the simplest safe method that can actually do the job.

- Portable ramp: Best when you ship regularly from the same location, can invest in equipment, and need a “plug-in dock” for palletized freight.

- Truck-mounted crane / Hiab: Best when freight is too heavy/large/oddly shaped for standard methods and needs to be lifted or placed where a ramp or liftgate cannot reach.

- Liftgate, or forklift: Still your default for most LTL shipments. If your freight is within normal liftgate limits and you only ship occasionally, a liftgate or a terminal service will usually be simpler and cheaper than specialized gear.

Dock alternatives: portable ramps, cranes, & truck-mounted liftsifts FAQ

Do I need a loading ramp if I already use liftgates?

Not necessarily. If you ship only occasionally and your freight fits standard liftgate limits, requesting a liftgate at pickup/delivery is often enough. A ramp becomes a good investment option when you ship frequently from the same place and want a long-term dock alternative.

Can I use a portable ramp with a pallet jack, or do I need a forklift?

Some ramps are designed for forklifts only, others can accommodate pallet jacks as well. Check the manufacturer’s specifications, including surface type, slope, and capacity, before you plan your loading method.

When is a crane or Hiab absolutely necessary?

You typically need crane-type equipment when the freight is too heavy for a liftgate/forklift, must be lifted over obstacles or onto elevated areas, or the site makes it impossible to back a truck close enough for ramps or standard gear to work.

Can the carrier always provide a truck-mounted crane?

Not always. Some carriers offer Hiab/knuckleboom trucks, others work with third-party crane providers, and some do not offer crane service at all. It is important to flag this need at quote time so the right equipment can be sourced.

What if I only occasionally have an oversized/heavy shipment?

For rare, oversized, or extra-heavy moves, it often makes sense to book a one-off crane or Hiab service instead of investing in permanent equipment. Your shipping provider can help you compare options based on weight, size, and site constraints.

Still not sure what to choose?

If you are unsure whether a portable ramp, liftgate, or crane/Hiab is the safest and most economical way to handle your shipment, you can note that when requesting a quote with Freightera. Share details of your freight and your locations, and our team can help you choose the right loading/unloading setup before you book.