When FTL Beats LTL on Total Cost (Case Examples)

Examples of when FTL can be a cheaper, safer, and more reliable choice for your business

If your load is big, long, time-sensitive, fragile, or needs special equipment, FTL pricing can win on total cost per pallet, and often on risk and speed too.

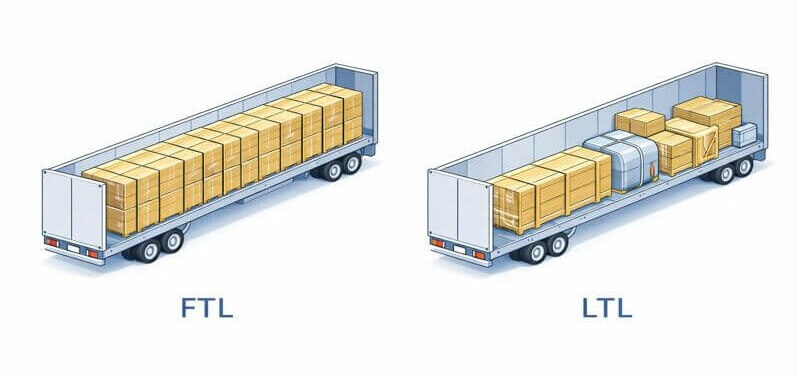

LTL vs. FTL cost patterns at a glance

- For small, flexible shipments, LTL usually wins on price.

- For bigger or longer freight on long lanes, FTL often becomes cheaper once your shipment reaches linear-foot or cubic dimension minimums.

- For tight appointment windows, FTL is usually more reliable because it runs directly from pick up to delivery, with no terminal transfers.

- For fragile or high-value goods, FTL reduces handling (it’s loaded once, and unloaded once), which lowers the risk of damage and claims.

- For oversize or open-deck needs, FTL flatbed, step-deck, or RGN is typically the only practical option.

- For LTL shipping within the USA and cross border USA⇄Canada, you have to declare the correct NMFC class while quoting, or risk re-classification fees. FTL doesn’t use freight classing, so there’s no risk of extra charges based on freight reclassification.

Case examples: When shipping FTL is a better choice than LTL

1) Case 1: “Near-full” truck / large pallet count on a long lane

Scenario: You’re shipping 10 pallets (~12,000 lb), 48″ × 40″ × 60″ each, Chicago → Dallas (~925 miles).

If you choose LTL: You’re paying for a lot of trailer space over a long distance. Many carriers apply cubic or linear-foot minimums, so your LTL price may start to near the FTL (dedicated truck) price anyway.

Why FTL often wins: It’s one truck, one pickup, one delivery, no terminals in between. With fewer touches and fewer chances for delay, the total truckload price can beat LTL once those cubic or linear-foot minimums kick in, especially on longer lanes.

Rule of thumb: Once you reach around 8-12 pallets or are sure to use at least half to three-quarters of a trailer on a longer lane, always get both an LTL and an FTL quote and compare them.

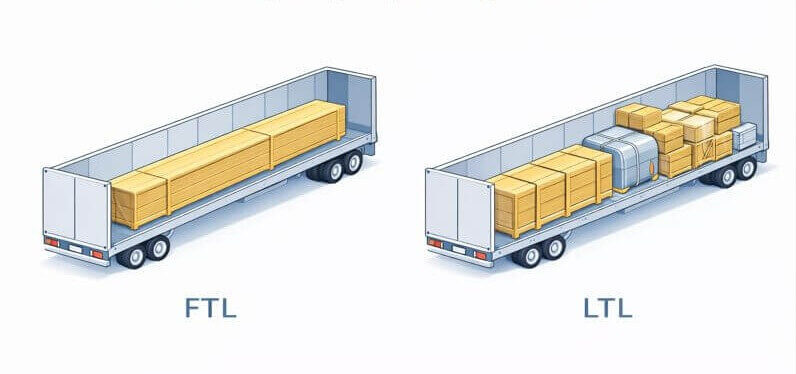

2) Case 2: Long, oddly shaped, or high-cube pieces

Scenario: You’re shipping two crated machine parts, each 12′ long × 44″ wide × 44″ high, total 4,000 lb.

If you choose LTL: Long pieces can trigger overlength or cubic rules, special handling, and higher minimum charges. You also risk reweigh/remeasurement and reclassification fees if the measured size or density is different from what you declared.

Why FTL often wins: A 53′ dry van FTL (or a step-deck if you need extra height or special loading) loads once and runs direct. There’s no NMFC classing in FTL pricing, so there’s no reclassification fee risk, and the pricing is simpler to understand.

Tip: If your pieces are over typical LTL length thresholds or take up a long strip of floor space, make sure to get both FTL and LTL quotes, and compare them.

3) Case 3: Tight appointment times / time-critical delivery

Scenario: You’re shipping several pallets with a delivery requirement of “Tuesday between 8-10 a.m. only.”

If you choose LTL: LTL moves through terminals and local delivery routes, and that’s why all LTL delivery windows are estimated. Everything has to line up perfectly for that narrow window. A missed window can mean redelivery, storage, and extra handling, especially with driver Hours of Service (HOS) limits in play.

Why FTL often wins: A dedicated truck is loaded and then driven straight to the delivery location. There are fewer moving parts, fewer handoffs, and better control over exact timing, which usually means fewer surprise fees and higher chances of meeting the delivery window.

4) Case 4: Fragile or high-value product

Scenario: You’re shipping 8-10 pallets of fragile fixtures.

In LTL: Freight may be handled multiple times (in and out of terminals), which increases the chance of damage.

Why FTL often wins: Full truckload means your freight is loaded once, and unloaded once. You can seal the trailer if needed and keep handling to a minimum, which usually means fewer damage claims and fewer delays, which is especially important for expensive or delicate freight.

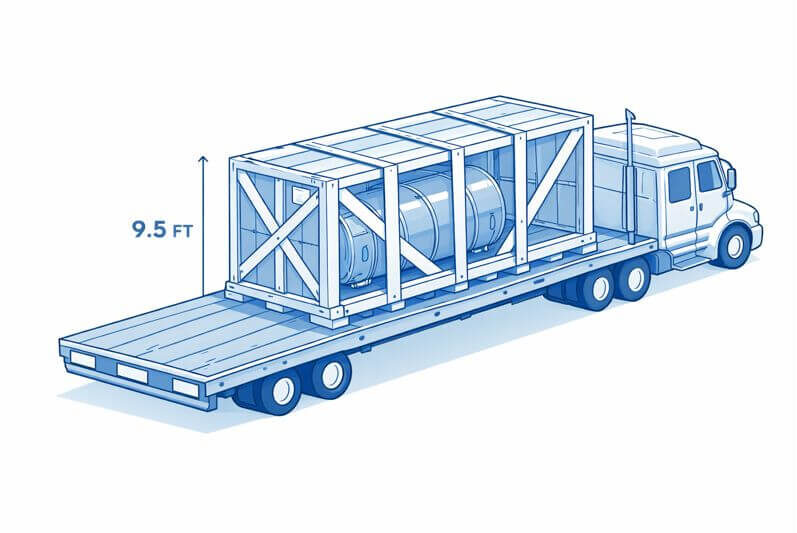

5) Case 5: Open-deck or oversize requirements

Scenario: You’re shipping one 9.5-ft-tall crated compressor.

In LTL: A standard dry van can’t handle that height, and piecing together an LTL solution with special handling is often impractical or simply unavailable.

Why FTL wins outright: An FTL flatbed, step-deck, or RGN with proper securement (and permits/escorts if needed) is the correct tool for the job. You send the equipment on one dedicated trip on the right trailer, instead of trying to force oversize freight through an LTL terminal network.

Quick decision guide: When to get an FTL quote

Use this as a fast checklist when you’re deciding whether to ship FTL or LTL. If two or more of the items below apply to you, it’s almost always worth comparing LTL vs. FTL side by side:

- Pallet count / cube: If you’re nearing half a trailer or have more than 8-10 pallets, check FTL quotes as well, and compare them to LTL quotes.

- Overlength / high cube: If you have long or bulky pieces that may trigger linear-foot or cubic rules in LTL, check FTL quotes.

- Deadlines / appointments: If you have tight delivery windows, just-in-time supply, or crews waiting on site, FTL is usually more reliable.

- Fragile or high-value: If you have a low tolerance for damage or loss, FTL’s “load once, unload once” model is safer.

- Special equipment: If you need a reefer with a strict temperature limit, flatbed/step-deck/RGN truck, tarping, or oversize permits, you’re firmly in FTL territory.

- “In-between” loads (Partial Truckload (PTL) gray zone): If your shipment feels “in between” LTL and a full truck (too big for cheap LTL, but not quite a full trailer) ask about partial truckload (PTL) as well. On some lanes, PTL can land between LTL and FTL on both price and handling.

When FTL beats LTL on total cost FAQ

Is there a strict pallet cutoff where FTL is cheaper?

There’s no hard rule, but once you’re around 8-12 pallets or taking up a long strip of floor space in the trailer (especially on a long lane) FTL often beats LTL on total cost per pallet, and usually on risk and timing too. In these cases, it would be best to compare both options.

Why do driver Hours of Service (HOS) rules matter for my freight quote?

Commercial drivers can only drive a set number of hours per day and week (for example, up to 11 hours of driving within a 14-hour work window in the USA. In Canada, drivers generally may drive up to 13 hours in a day, within a 16-hour work window). If loading or delivery runs long, they may run out of legal driving time, which can lead to detention, layovers, missed appointments, and rescheduling, all of which can add fees.

Does shipping FTL avoid reclassification fees?

Yes. NMFC class and density tables apply to LTL pricing only in the USA (and cross border USA⇄Canada). FTL is priced on lane + equipment/accessorials + market conditions/fuel surcharge, so there’s no freight classing or reclassification fees in full truckload.

When is rail FTL a good alternative to road?

Rail-based FTL or intermodal makes sense on very long lanes when you have a flexible delivery window. It’s often cheaper and lower-emission than road-only trucking, with the trade-off of a slightly longer transit time.

Not sure if FTL would be a more affordable option for your shipment?

You don’t have to guess.

Send your lane, pallet count, dimensions, weight, and timing to [email protected], and our team can compare LTL vs. FTL (road and rail where available) for you. Alternatively, get your instant online FTL quote online on Freightera.

We’ll help you pick the option with the best total cost, risk, and timing for your shipment, so that you’re not overpaying for LTL when a full truckload would do better.