How FTL Freight Shipping Works, and When to Use It

Learn what full truckload freight shipping is, how it works in practice, and when to use it for your business

In this guide, you’ll learn what full truckload (FTL) freight shipping is, how it actually works, and when it’s a better choice than LTL, so you can pick the right option with confidence and fewer surprises.

What is FTL freight shipping?

If your load fills more than half the trailer, or needs its own truck due to size, weight, timing, or handling needs, full truckload (FTL) shipping allows you to rent a dedicated truck.

Typical FTL shipments use these types of trucks:

- A 53′ dry van for standard, non-temperature-controlled freight

- A reefer (temperature-controlled trailer) for chilled, frozen, or protect-from-heat products

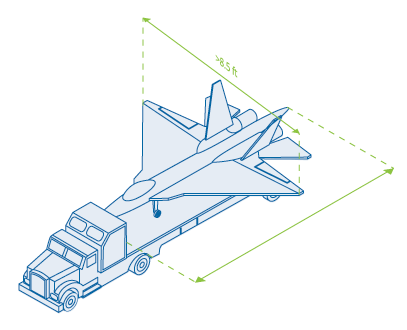

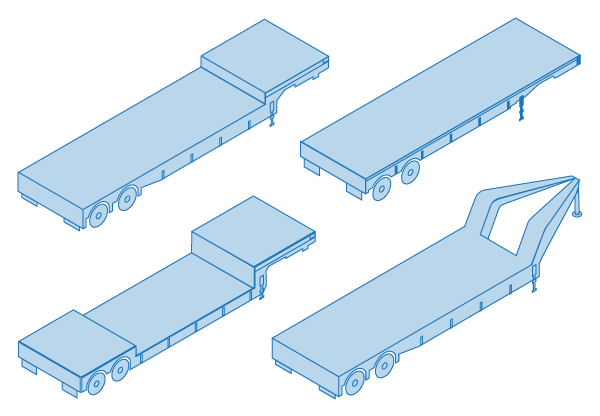

- A flatbed, step-deck, or gooseneck (RGN) for machinery, tall/oversize freight, or crane/forklift loading

Instead of going through a terminal network like LTL, an FTL shipment is usually loaded once at the pickup location, then driven directly to the delivery location and unloaded there, with no cross-docking in between.

This “one truck, one shipper, one route” structure is why FTL is often faster than LTL, and has a lower risk of loss or damage than LTL for the right kind of load.

When to use FTL freight shipping

Use FTL when one or more of the following applies to your shipment:

1) You have many pallets or bulky freight

- Rough rule of thumb: more than 8-10 pallets, more than 15,000 lbs, or freight that takes up a large portion of a 53′ trailer;

- Long, bulky pieces that would trigger linear-feet / cubic capacity rules in LTL are often cheaper and simpler when shipped as FTL.

2) Timing is essential

- Your production schedule, project timeline, or crew availability depends on on-time delivery; your shipment has to arrive on a specific day or within a tight window;

- The shipper/receiver has strict appointment times;

3) Your freight is fragile or high-value

- You want to minimize manual handling (instead of your pallets being cross-docked through multiple LTL terminals, an FTL load is loaded once, sealed, driven straight to the receiver, and unloaded once at destination).

4) You need special equipment / a special type of truck

- Reefer with a specific temperature set-point;

- Flatbed / step-deck / RGN for machinery or tall freight;

- Conestoga/curtain-side for open-deck freight that still needs weather protection

How FTL shipping works in practice

Here’s what a typical full truckload move looks like from a shipper’s point of view:

1) Plan and prepare your load

- Decide on the right truck type (dry van, reefer, flatbed, step-deck, etc.)

- Package and secure your freight so it can be safely transported (palletize, crate, block/brace, or prepare tie-down points for open-deck).

2) Gather accurate shipment details

- Pickup and delivery addresses and hours of operation

- Contact names and phone numbers on both ends

- Dimensions and weight of each handling unit (including packaging) – this is important when determining the size or number of trucks required to ship your cargo.

- Any special services, or pick up/delivery constraints (e.g. appointments, tarping, site access limits, etc.).

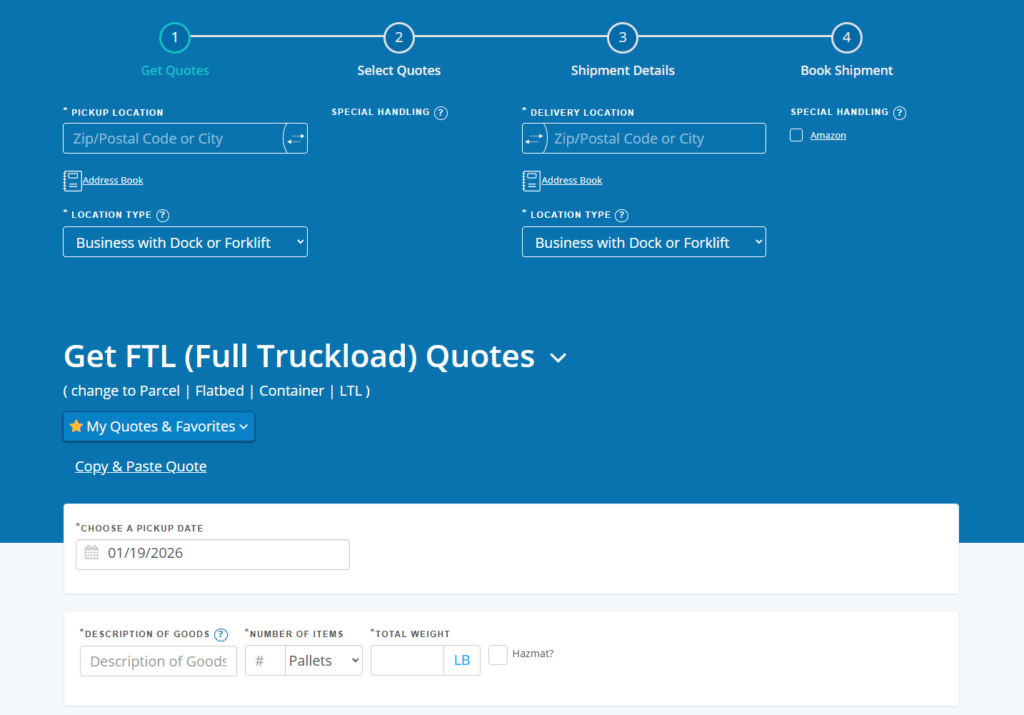

3) Get FTL quotes

The pricing you see will reflect the lane (origin → destination), equipment type, fuel prices, and any accessorials you selected.

4) Book your truck

- Choose the service and carrier that matches your schedule and budget.

- Confirm pickup date/time window and any appointment requirements.

5) Pickup and loading

- The truck arrives at the pick up location.

- The freight is loaded, secured, and the trailer may be sealed if appropriate.

- The driver departs directly toward the delivery location.

6) Linehaul and transit

- The truck usually goes point-to-point (straight from the pick up location to the delivery location), without terminal transfers.

- Transit time is governed by distance, driver Hours of Service (HOS), traffic, and weather.

7) Delivery and unloading

- At the destination, the driver checks in, backs into the dock or unloading area, and your freight is unloaded.

- Any detention or layover risk depends on how closely actual loading/unloading matches what was booked.

How Freightera helps with time-sensitive and full truckload shipments

- FTL pricing and truck availability can shift quickly with demand, season, and lane capacity.

- While our platform shows real-time rates from carriers across Canada and the USA, many full truckload shipments benefit from a quick confirmation of equipment, schedule, and routing directly with our carrier network.

- Because Freightera works closely with hundreds of vetted carriers in the USA and Canada, we aren’t as restricted by capacity issues, so we can often match your shipment to a truck that fits your timing, equipment needs, and routes – even when your schedules are tight, or when the shipping requirements are specific.

- If your shipment is time-critical, high-value, or requires special handling, the quickest way to secure the right truck is to send us the shipment details, and we’ll check availability and confirm options for you.

- Email [email protected] with the shipment information, and our team will help you plan the move and avoid surprises. 🙂

FTL freight shipping FAQ

Is FTL always faster than LTL?

Generally yes. With direct linehaul and fewer stops, FTL shipments usually reach the receiver faster than LTL. Actual delivery time still depends on distance, traffic, driver HOS limits, appointments, and weather.

Does FTL mean my shipment needs to take an entire truck? How “full” should a truck be to justify FTL?

There’s no fixed cutoff, but many shippers start considering FTL around 6-10 pallets, or when the freight uses a significant share of trailer space, or triggers overlength rules (meaning your shipment is simply too long to justify standard pricing) in LTL. Deadlines, product sensitivity, and damage risk can justify FTL even for slightly smaller loads.

Who handles securement on FTL shipments?

Drivers are responsible for leaving with a legally secured load, but shippers must provide freight that can be secured safely: strong packaging, accessible tie-down points, and accurate weight/dimensions.

Is FTL more expensive than LTL?

On a per-shipment basis, FTL often has a higher total cost because you’re reserving the entire truck. But per pallet or per pound, FTL can be more cost-effective once your shipment is large enough, especially on longer lanes or when LTL would trigger special pricing rules, such as linear-feet/cubic, or high accessorials.

Can FTL be a greener or cheaper option over long distances?

Sometimes. Rail FTL or intermodal can reduce emissions and cost on the right corridors if your transit time is flexible. You trade a bit of speed for more stable pricing and lower environmental impact.